Silicone tools and multiple component tools

For LSR- and HCR-parts of highest quality

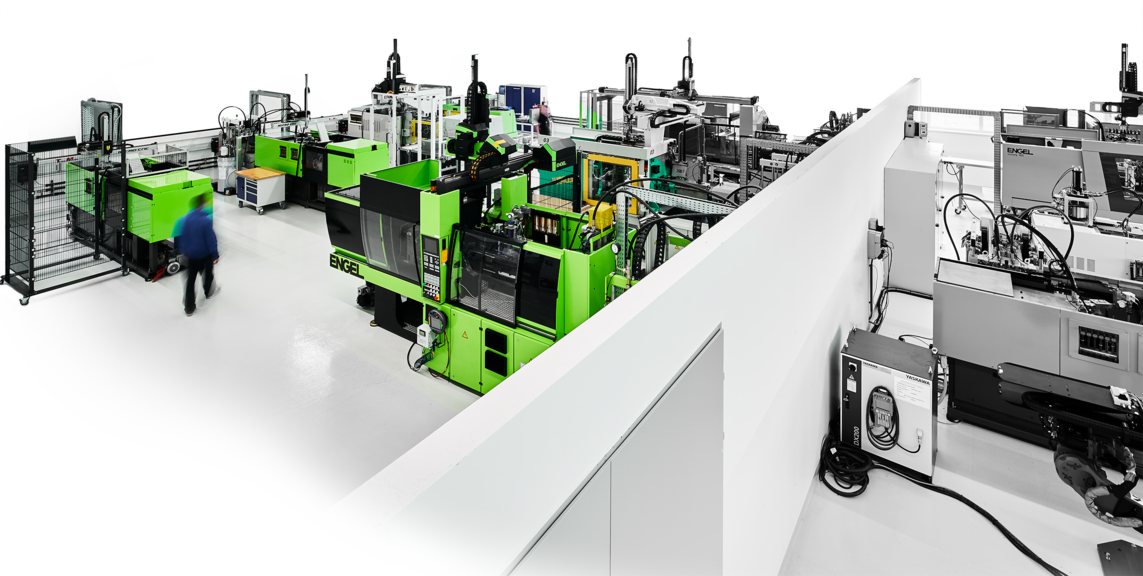

We have a wealth of expertise that allows us to achieve high throughputs and guarantee the best possible quality thanks to automated processes.

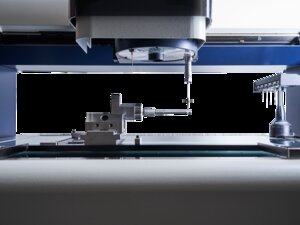

Before leaving our facility, all tools undergo thorough testing in our application technology department to ensure that nothing is left to chance.

- Our systems are used to test all tools.

- Production of components with high tolerance and surface quality demands.

- Optical and tactile measurement of complex geometries.

Diligence

makes

the Difference.

Your parts with our tools

Are you seeking an experienced partner to plan and execute your project with expertise?

ACH Solution offers the know-how and decades of experience you need.

We work closely with our customers throughout the design process to ensure high-quality, reproducible articles. Our tools are designed for efficient series production with minimal material consumption.

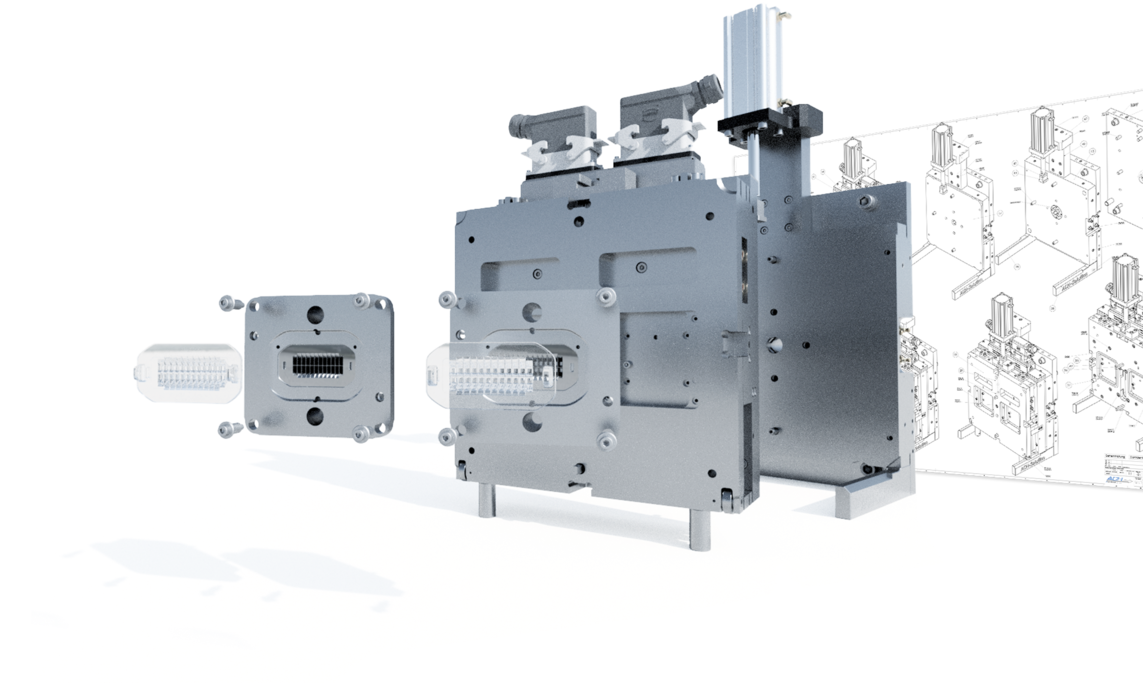

Tools on highest level

- LSR-tools.

- HTV-tools.

- Multi-component-tools.

- Up to 128 cavities.

FROM DRAWING TO FINISHED TOOL

After construction, our tools go through several production processes. Our top priority at every step is to take the utmost diligence.

Thanks to this care, we guarantee a flawless end product.

Automated and High-Precision Production

Our in-house capabilities include milling, cylindrical grinding, and eroding. Our well-designed processes and automated production lines enable us to manufacture with high productivity.

Quality assurance: measurement of hardness using optical and tactile methods.

We measure all tools precisely in our own measuring center and document the results accordingly.

Assembly

Finally, our tools are assembled under close supervision to ensure the highest level of accuracy and care.

Initial Sampling, Customer Acceptance,

and Training

Our tools undergo thorough testing in our extensive application technology center to ensure flawless quality of the delivered systems.

Tool acceptance takes place directly at our premises, where we provide customers with all necessary measuring and testing instruments. Our employees work closely with the customer to check the tool in detail, leaving nothing to chance.

QUALITY THAT REACHES YOU

Our products are produced with energy, passion, professionalism, quality, and diligence.

These values guide us throughout all of our processes, from the initial contact to the packaging and delivery of the final product.

OUR SERVICE-PLUS

Our service partnership begins with tool delivery.

ACH Solution provides targeted training for you and your employees to ensure problem-free commissioning and an optimal start to your production process.

Spare parts request

Request spare parts online

In our customer portal, you can conveniently request and retrieve spare parts and access all relevant product details.